OAKMOBILE

OAKBOT + Mobility trolley and clamping system

OAKSTATION

OAKBOT + Stationary system

OAKBOT BY EPUR,

AGILE ROBOTICS FOR

WOOD CONSTRUCTION

Created by two timbermen whose objective was to simplify, optimize, and secure the work of craftsmen in their field, EPUR has designed the OAKBOT: The world’s first modular digital control milling machine.

Formerly, as timbermen, we were faced with the dilemma between (electric) portable tools and the large CNCs. Today, our revolutionary solution improves upon this offering.

The OAKBOT allows us to benefit from the advantages of CNC in terms of productivity and precision while preserving the craftsmanship and unique touch of wood.

The robot allows you to work safely as it operates autonomously. And with its high productivity, you will gain added value, which will help improve your business. Furthermore, our innovative, precise, and reliable robot features an intuitive and user-friendly control panel.

Now you can truly unleash your creativity while we take care of the programming!

Affirmed values…

By manufacturing and marketing our products from a small village in the southern French Pyrenees, our company creates employment opportunities in rural areas and helps to stimulate the revival of industrialization in the more remote zones through the production of MADE IN FRANCE machine tools.

ASSEMBLAGES & JOINTS

Straight tenon and mortise

Double member

Male and female dovetail joint

Halving joint

Double straight and skewed tenon Double mortise

Notched joint

Variations

Angled dovetail joint

Column cap dovetail joint

Skewed tenon and mortise

Notched joint

Actualités

Restez à l’affût de nos dernières innovations en consultant notre rubrique actualités !

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Suivez nous sur les réseaux !

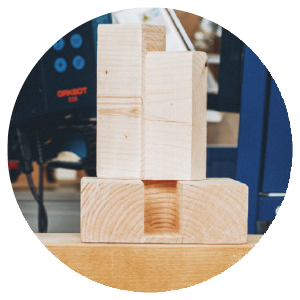

💪 RÉSISTANCE MAXIMALE — Grâce à nos usinages précis sur charpentes bois. La solidité de vos charpentes repose sur des assemblages parfaits. Et la bonne nouvelle, c'est que notre robot charpentier a été créé pour ça. Nos techniques d’usinage garantissent une résistance maximale et une durabilité à toute épreuve. Alors, vous vous décidez quand à ENFIN améliorer votre production en atelier ? Et la petite 🍒 c'est que l'investissement est rentabilisé en peu de temps. #détailsepur #machinecharpente #machinebois #RobotCharpentier #MadeInFrance #Charpente #fermette #CNC #EPUR 🦾#OAKBOT 🚅#OAKMOBILE 🏭#OAKSTATION #ossaturebois #mob #Woodworking #travaildubois #WoodworkingTechnology #Woodconstruction #cncmachinery #WoodworkingTools #OakFraming #TimberFraming #TimberFrame #carpenter #powertools #carpentrylife #carpentrymachinery #woodworker #wooddesign #WoodworkersOfInstagram @follower @fans

📐 BIAIS MAÎTRISÉS — Usinez vos charpentes de biais. Facilement. Maîtrisez chaque biais avec une précision exceptionnelle grâce à notre technologie avancée. Et si vous faites le compte, on est sûrement moins chers que tous nos concurrents. Obtenez des assemblages parfaitement ajustés à chaque coupe. #détailsepur #machinecharpente #machinebois #RobotCharpentier #MadeInFrance #constructionbois #assemblage #Charpente #fermette #EPUR 🦾#OAKBOT 🚅#OAKMOBILE 🏭#OAKSTATION #ossaturebois #mob #Woodworking #WoodworkingTechnology #Woodconstruction #cncmachinery #WoodworkingTools #OakFraming #TimberFraming #TimberFrame #carpenter #powertools #carpentrylife #carpentrymachinery #woodworker #wooddesign #WoodworkersOfInstagram @followers @fans

📏 POTEAUX STANDARDISÉS — Facilitez vos constructions de charpente Usinez plusieurs têtes de poteaux identiques en un temps record. Grâce à notre robot de charpente innovant. Et avec un coût d'achat IMBATTABLE. La standardisation au service de votre cadence de production, pour plus d’efficacité et moins d’erreurs. #détailsepur #machinecharpente #machinebois #RobotCharpentier #MadeInFrance #FilièreBois #constructionbois #assemblage #Charpente #fermette #CNC #EPUR 🦾#OAKBOT 🚅#OAKMOBILE 🏭#OAKSTATION #ossaturebois #mob #Woodworking #travaildubois #WoodworkingTechnology #Woodconstruction #cncmachinery #WoodworkingTools #TimberFraming #TimberFrame #carpenter #carpentrylife #carpentrymachinery #wooddesign #WoodworkersOfInstagram @fans @followers

Contact US

We have been on the market for a few years, but we recently renewed our website.

Currently, we are still optimizing our English pages. In the meantime, please do not hesitate to contact us if you would like more information. Our representatives will be happy to assist you!